SLA 3D printing, also known as stereolithography, is a popular resin 3D printing process used to create highly accurate, isotropic, and watertight prototypes and end-use parts. SLA parts have a smooth surface finish and fine features, making them ideal for a wide range of applications. This blog post will cover the basics of SLA 3D printing, its applications, and its advantages and disadvantages.

What is SLA 3D Printing?

SLA 3D printing is an additive manufacturing process that uses a light source to cure liquid resin into hardened plastic. It is a vat polymerization process, meaning that the printing takes place in a vat of liquid resin.

The technology relies on the precise curing of layers of resin, which are gradually built up to form solid, three-dimensional parts with high detail and accuracy.

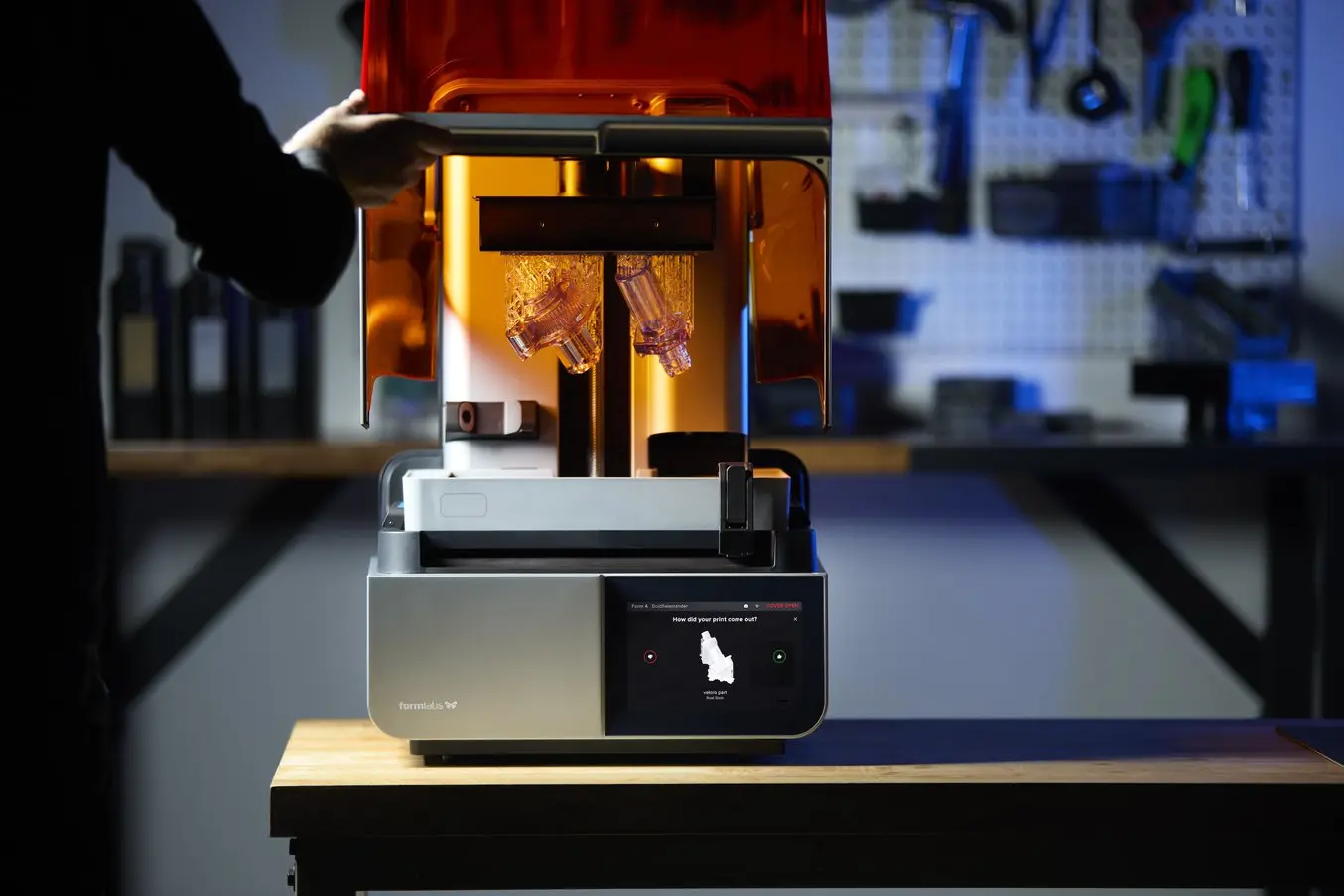

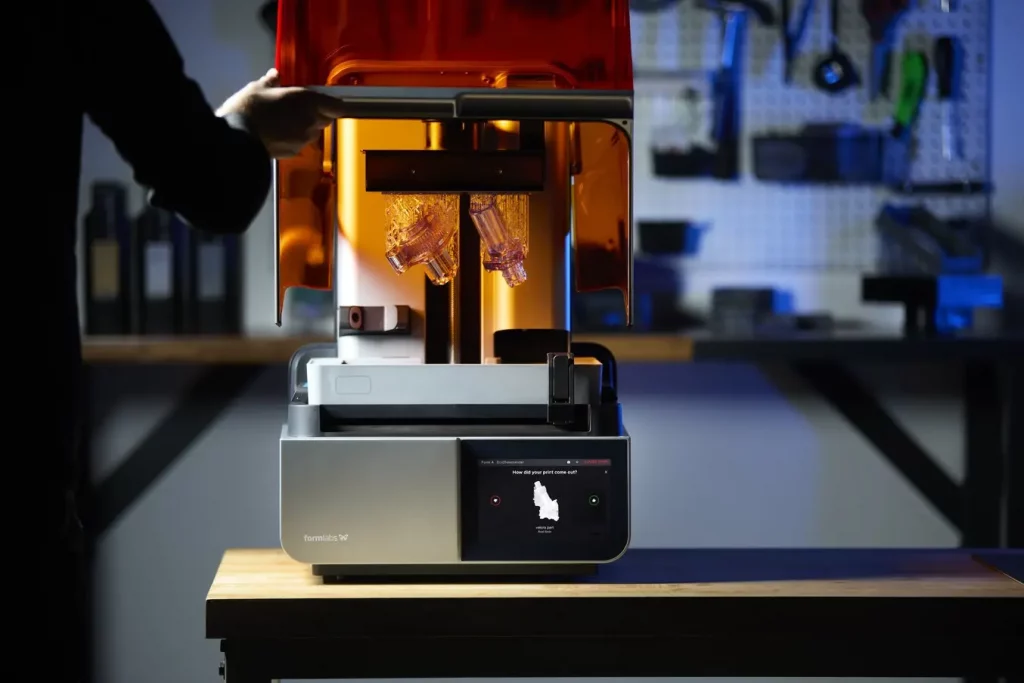

Source: FormLabs

How Does SLA 3D Printing Work?

SLA 3D printing uses a UV laser to selectively cure a photopolymer resin layer by layer. The process begins with a build platform submerged in a vat of liquid photopolymer resin. A UV laser beam, focused by a set of mirrors called galvos, traces the desired pattern on the resin surface.

The exposed resin cures and solidifies, bonding to the previous layer. This process repeats, layer by layer, until the 3D object is complete. Since a single pass of the laser doesn’t fully cure the resin, subsequent passes fuse the layers together, creating a solid, isotropic part.

Types of SLA 3D Printing

There are different types of SLA 3D printing, each offering distinct advantages depending on the specific application. While traditional SLA uses a laser to cure the resin, other variations of the technology have emerged.

- Laser SLA: This original method uses a UV laser to cure the resin layer by layer. It’s highly accurate but can be slower than other resin printing technologies.

- Digital Light Processing (DLP): DLP uses a digital projector to cure an entire layer of resin at once, making it faster than laser SLA. However, DLP printers can have lower accuracy, especially with larger builds, due to pixel distortion.

- Masked Stereolithography (MSLA) / LCD 3D Printing: MSLA, often used synonymously with LCD 3D printing, uses an LCD screen to mask the light from an array of LEDs, curing only the desired areas of the resin. It offers fast printing speeds comparable to DLP. The resolution depends on the LCD screen’s pixel density, with smaller pixels enabling higher resolution but potentially slowing down print speed.

Advantages of SLA 3D Printing

SLA 3D printing offers several advantages over other 3D printing technologies:

- High Accuracy and Precision: SLA is one of the most accurate 3D printing technologies available. It can produce parts with intricate details and tight tolerances, making it ideal for prototyping and producing end-use parts that require high precision.

- Smooth Surface Finish: SLA produces parts with exceptionally smooth surface finishes. This makes it an excellent choice for creating visually appealing prototypes and models.

- Isotropy: SLA parts have isotropic mechanical properties, meaning they have consistent strength in all directions. This is due to the chemical bonding between layers during the curing process.

- Watertightness: SLA printed objects are continuous, making them suitable for applications requiring watertight or airtight seals.

- Wide Range of Materials: SLA offers a wide variety of material options, including clear, flexible, and durable resins, each with specific mechanical properties.

Disadvantages of SLA 3D Printing

Despite its advantages, SLA 3D printing also has some drawbacks:

- Brittleness: SLA parts can be brittle, making them unsuitable for applications requiring high impact resistance.

- UV Degradation: SLA parts can degrade over time when exposed to UV light, potentially becoming brittle or discolored.

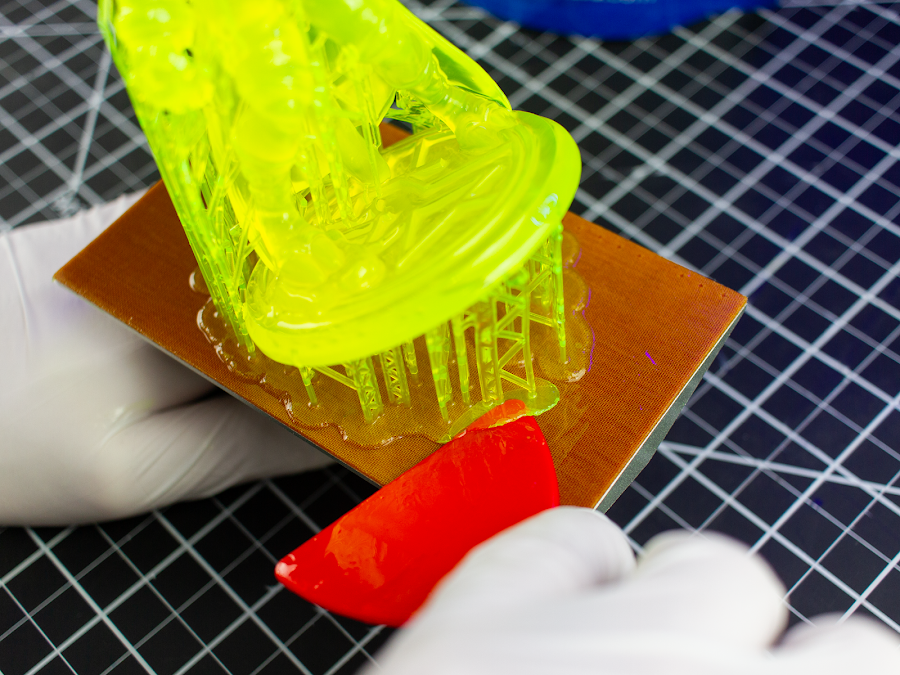

- Support Structures: SLA printing requires support structures, which need to be manually removed and can leave marks on the part’s surface.

- Limited Build Volume: SLA printers generally have smaller build volumes than some other 3D printing technologies, limiting the maximum size of printable parts.

- Post-Processing: Achieving optimal mechanical properties often requires post-curing the printed parts under UV light.

Source: Matt Hackers

Applications of SLA 3D Printing

SLA 3D printing is widely used across various industries due to its versatility and precision. It is particularly beneficial for creating functional prototypes in engineering, automotive, and aerospace industries, where accuracy and detail are critical for product development.

- Engineering and Product Design: Rapid prototyping, concept models, functional prototypes, validation testing

- Manufacturing: Manufacturing aids (jigs and fixtures), rapid tooling (injection molding, thermoforming, silicone molding, blow molding, metal casting), low-volume manufacturing, mass customization

- Automotive: Rapid prototyping, rapid tooling, manufacturing aids, end-use, aftermarket, and custom parts

- Aerospace: Rapid prototyping, rapid tooling, manufacturing aids, end-use, replacement, and custom parts. For example, SLA 3D printed parts have been used in testing on the International Space Station and in manufacturing for commercial airlines.

- Dental: Crown and bridge models, clear aligner and Hawley retainer models, surgical guides, splints and occlusal guards, patterns for casting and pressing, dentures

- Medical: Anatomical models for surgical planning, medical devices and surgical instruments, orthotics and prosthetics One notable success story is the use of SLA printing in the production of hearing aids. Today, SLA printing accounts for the production of 97% of all hearing aids globally.

- Education: Research and development, fab labs and makerspaces, teaching tools across disciplines

- Entertainment: Hyper-realistic sculptures, character models, prop making

- Jewelry: Lost-wax casting (investment casting), customized high-fidelity prototypes, master patterns for rubber molding

Conclusion

SLA 3D printing in Malaysia is a powerful and versatile technology that offers a unique combination of accuracy, surface finish, and material properties. SLA 3D printing has become an essential tool in various industries by enabling the creation of highly detailed and precise parts, from prototypes to end-use products. As the technology continues to evolve and become more accessible, we can expect SLA 3D printing to play an even greater role in shaping the future of product development and manufacturing.

To explore more about the vast world of 3D printing and to deepen your understanding of different technologies, we invite you to check out our additional articles on resin 3D printing and FDM 3D printing. Each piece offers in-depth insights, practical tips, and the latest trends that can help you make informed decisions and enhance your 3D printing projects.

Whether you’re a novice curious about starting your first print or a seasoned professional looking to optimize your workflow, these articles are your gateway to mastering the art of 3D printing.